Entrepreneurial Support Program 2022

- Principal Investigator

-

Waseda University

Chiharu Tokoro

- Adopted Theme

Creation of a New Circulation Value Chain for Lithium-Ion Batteries Using a Novel Electric Pulse Method

- Subject of Research

- Creation of a New Circulation Value Chain for Lithium-Ion Batteries Using a Novel Electric Pulse Method

- Overview

-

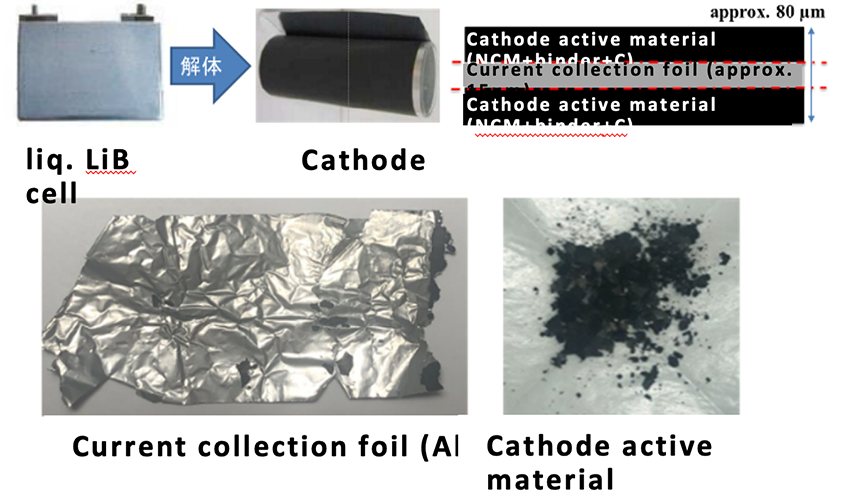

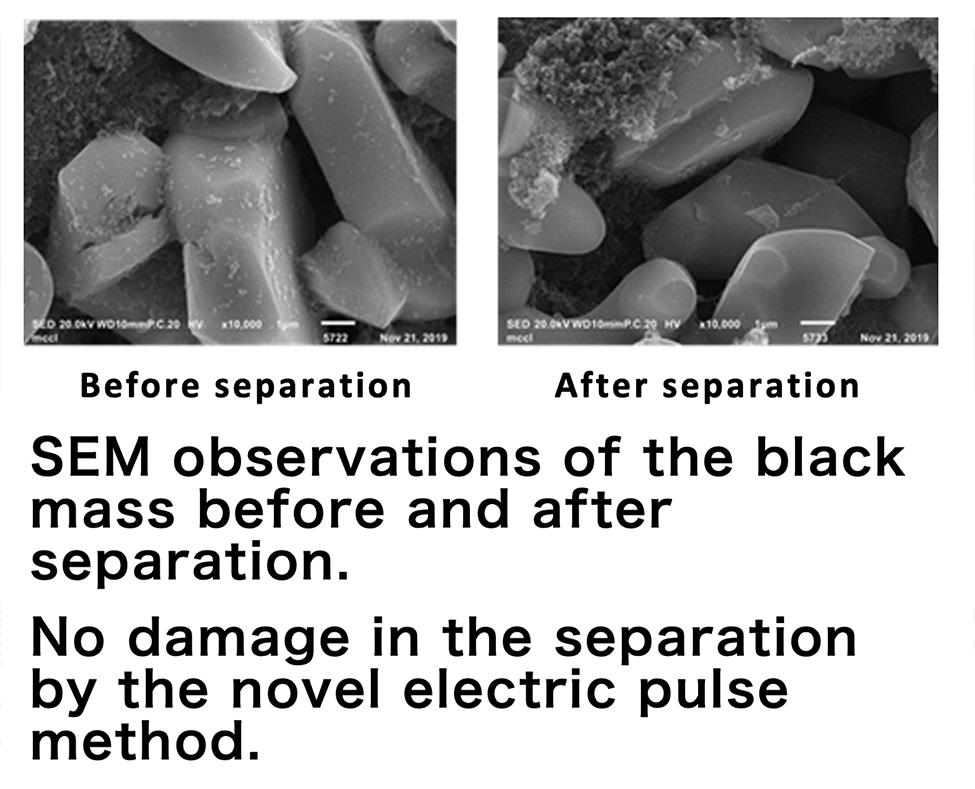

The demand for lithium ion batteries is expected to increase exponentially in order to achieve carbon neutrality. We will develop a new resource recycling process to recover the "black mass" (cathode active material particles consisting of lithium, cobalt and nickel), using an innovative separation process based on a new electric pulse method, which does not alter the highly valuable original material. Also, a global business for the production of recycled black mass will be established.

- Business Models(when applying)

The company will act as a recycler that procures and recycles spent lithium-ion batteries in order to sell the cathode materials to battery manufacturers as a commodity. The low cost of recycling and the high degree of difficulty in imitating the technology that makes this recycling process feasible are the sources of the company's competitiveness. When a large initial investment and operating capital are required, the company will consider establishing a joint venture plant with either a recycling company or a metal refining company as potential backers.

- Activity Planning(when applying)

-

・To quantitatively clarify the relationship between the physical properties of various lithium-ion batteries and electric pulse conditions via experiments and simulation.

・To find out the electrical pulse and pretreatment conditions that can achieve an stable and accurate separation of various types of adhesion between the current collection foil and the cathode active material particles.

・To regenerate the recovered black mass as cathode active material and confirm its battery performance.

・To compare with existing regeneration methods, we will examine the electric pulse conditions and pre/post treatment conditions that guarantee superior results